Анализ влияния последних политик и правил в отрасли литиевых батарей на оборудование

Под воздействием глобальной волны энергетического перехода отрасль литиевых аккумуляторов переживает взрывной рост. Однако возможности и проблемы сосуществуют, поскольку ряд политик и правил, введенных как на внутреннем, так и на международном уровне, значительно повысили производственные пороги для производителей литиевого оборудования и глубоко повлияли на их экспортные стратегии. В этой статье систематически анализируются конкретные требования этих политик и правил и их влияние, а также изучаются способы реагирования.

1. Внутренняя политика и правила:

1.1 Стимулирование модернизации производства и регулирование экспортной логистики 1. «Правила кодирования литий-ионных аккумуляторов» (GB/T 45565—2025) - Планируется к реализации (1 ноября 2025 г.):

- Требования: Все вновь произведенные литий-ионные аккумуляторы (от отдельных элементов до систем) должны иметь уникальный идентификационный код для обеспечения прослеживаемости на протяжении всего их жизненного цикла.

- Влияние на производство оборудования: Прямое и решающее. Производители оборудования должны модернизировать или разрабатывать новое оборудование для обеспечения высокоточных функций позиционирования и идентификации. Например: Машина для резки электродов аккумуляторов / Машина для нанесения покрытия на электроды аккумуляторных батарей: Необходимо интегрировать высокоточные системы кодирования или печати, чтобы гарантировать четкость и прослеживаемость кодировки электрода/рулона.

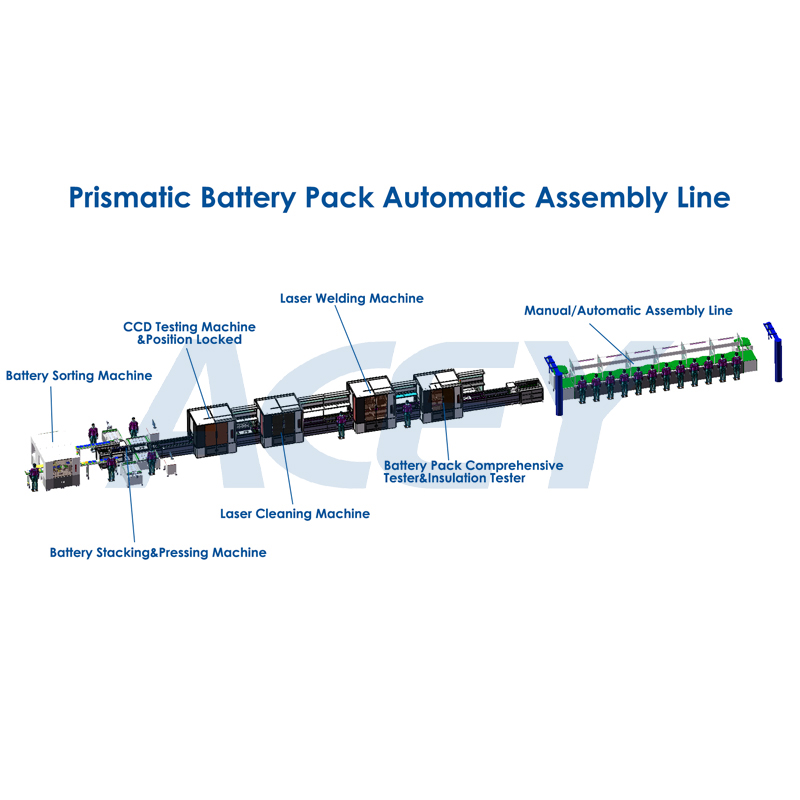

- Линия сборки литий-ионных аккумуляторов : Должны быть оснащены надежными системами считывания, привязки и записи кодов, чтобы гарантировать точную привязку кодовой информации каждой ячейки/модуля/системы.

- Основная задача: повышение точности, стабильности и возможностей взаимодействия оборудования с данными для удовлетворения потребностей в высокоскоростном и высокоточном кодировании в условиях крупномасштабного производства.

1.2 Обязательное управление сертификацией CCC для литий-ионных аккумуляторов и зарядных устройств, используемых в электровелосипедах - полностью вступит в силу в 2025 году:

- Требования: Обязательная сертификация, требующая, чтобы батареи были маркированы безопасным сроком службы и имели постоянный уникальный код, выдерживающий высокие температуры до 950°C.

- Оборудование для лазерной кодировки/гравировки: становится необходимым компонентом и должно соответствовать требованиям устойчивости к высоким температурам, чтобы гарантировать, что коды остаются идентифицируемыми в экстремальных условиях (например, при пожаре).

- Производственное оборудование (например, формовочные шкафы, емкостные шкафы, испытательные устройства): Требования к точности, стабильности и контролю безопасности (защита от перезаряда и переразряда, контроль температуры) еще больше ужесточаются, чтобы гарантировать соответствие показателей безопасности конечного продукта стандартам сертификации.

- Основные проблемы: Оборудование должно обеспечивать более надежную согласованность процесса и интегрировать более строгие функции мониторинга безопасности и прослеживаемости.

1.3 «Технические требования безопасности при перевозке литиевых батарей на судах» - Реализовано (1 мая 2025 г.):

- Требования: Стандартизировать стандарты безопасности для транспортировки литиевых батарей по воде (морским и внутренним водным путям), охватывающие такие аспекты, как упаковка, размещение, разделение и документирование.

- Влияние на экспорт оборудования: влияет на процесс логистики. Производители оборудования, экспортирующие устройства для производства литиевых батарей (особенно те, которые включают прототипы батарей или готовые батареи), должны гарантировать, что их методы упаковки и транспортные документы (такие как MSDS, отчеты об испытаниях UN38.3, транспортные сертификаты) полностью соответствуют новым правилам. Может возникнуть необходимость в сотрудничестве с профессиональными поставщиками логистических услуг для принятия специальных схем упаковки и транспортировки, соответствующих Международному кодексу морской перевозки опасных грузов (IMDG Code).

- Основные проблемы: рост сложности и затрат на соблюдение требований в экспортной логистике, повышение требований к управлению цепочками поставок.

2. Международная политика и правила: пересмотр доступа на рынок и повышение экспортных издержек

2.1 Директива ЕС по батареям:

Последнее обновление (с 1 января 2025 г.): Добавлены новые коды ООН 3551 (натрий-ионные батареи) и ООН 3552 (натрий-ионные батареи, установленные в оборудовании или упакованные вместе с оборудованием), а также соответствующие правила упаковки P911, LP903 и LP904.

- Влияние на экспорт оборудования: Соблюдение правил транспортировки: Оборудование, экспортирующее натрий-ионные батареи, должно строго соответствовать новым требованиям ООН по нумерации и упаковке.

- Требования к углеродному следу (будущее внимание): законопроект требует, чтобы с 2028 года батареи были декларированы и соответствовали все более низким пороговым значениям углеродного следа. Это означает для производителей оборудования: Его клиент (завод по производству аккумуляторов) нуждается в аккумуляторных продуктах с меньшим углеродным следом.

- Косвенное воздействие: Производителям оборудования, возможно, придется доказать, что их оборудование может помочь клиентам производить низкоуглеродные батареи (например, высокую энергоэффективность, совместимость с экологически чистой энергией и сокращение отходов), и даже им самим, возможно, придется предоставить данные об углеродном следе оборудования (будущая тенденция).

- Основная задача: постоянный мониторинг сложных нормативных обновлений (транспортировка, устойчивое развитие, комплексная проверка) и соблюдение все более строгих требований по охране окружающей среды.

2.2 Тарифная политика США:

Текущая ситуация в 2025 году: импортные пошлины на аккумуляторные батареи отечественного производства в Китае были повышены до 25%, а тарифы на аккумуляторные батареи, как ожидается, будут повышены до 25% в 2026 году.

- Влияние на экспорт оборудования: напрямую влияет на затраты и рыночные стратегии.

- Резкий рост затрат: норма прибыли от экспорта оборудования для производства аккумуляторных батарей существенно сократилась, и экспорт оборудования для хранения энергии вскоре столкнется с таким же давлением.

- Стратегическая корректировка: заставляет китайских производителей оборудования: Ищите другие зарубежные рынки (например, Европу, Юго-Восточную Азию и Южную Америку). Рассмотреть возможность создания производственных баз в третьих странах (например, Мексика, Юго-Восточная Азия) или на местных рынках целевых стран (например, США) для местной сборки или производства, чтобы избежать высоких тарифов («кривой экспорт»). Сотрудничать с местными предприятиями (через совместные предприятия или лицензирование технологий).

- Основная задача: реконфигурация глобальной цепочки поставок и локализация требуют огромных инвестиций и сложных операций.

2.3 Правила перевозки опасных грузов Международной ассоциации воздушного транспорта (ИАТА):

- Последнее требование (вступает в силу с 1 января 2025 г.): ужесточить контроль за транспортировкой литиевых батарей, в том числе: Пересмотрены новые инструкции по упаковке PI 965, Раздел II и PI 968, Раздел II (для литиевых батарей, установленных в оборудовании или упакованных вместе с оборудованием). Ввести более строгие ограничения по емкости/весу и требования к испытаниям упаковки для некоторых литиевых батарей (например, литий-металлических батарей с энергоемкостью более 100 Вт·ч).

- Влияние на экспорт оборудования: Стоимость экспорта оборудования (например, образцов и небольших устройств), содержащего литиевые батареи, воздушным транспортом возросла, а сам процесс стал более сложным. Необходимо убедиться, что батареи соответствуют последним стандартам авиаперевозок. Могут потребоваться дополнительные испытания упаковки и сертификация.

- Основная проблема: сложность и стоимость увеличения экспорта мелкосерийного и высокоскоростного оборудования.

3. Новые требования, предъявляемые международной политикой и правилами к производству оборудования

- Глобальная политика, в частности требования Директивы ЕС по аккумуляторным батареям к выбросам углекислого газа, оказывают глубокое влияние на концепции проектирования и производства оборудования:

- Требования к низкоуглеродному производству: Производителям оборудования необходимо разрабатывать оборудование с более высокой энергоэффективностью и меньшим потреблением энергии, а также учитывать выбросы углерода, образующиеся в процессе производства оборудования.

- Инновации в материалах и процессах: Оборудование, которое позволяет заводам по производству аккумуляторов использовать более экологически чистые материалы (например, катоды с низким содержанием кобальта или без него, кремний-углеродные аноды) и более устойчивые процессы (производство сухих электродов, обработка твердотельного электролита), будет более конкурентоспособным.

- Поддержка проектирования с учетом возможности вторичной переработки: конструкция оборудования должна учитывать удобство будущей разборки и переработки аккумуляторов (например, модульные конструкции, которые легко разделять).

- Возможность отслеживания данных: для соответствия требованиям паспорта аккумулятора ЕС оборудование должно обладать мощными возможностями сбора и передачи данных, а также регистрировать ключевые параметры в ходе производственного процесса (партия материала, потребление энергии, параметры процесса).

- Политический ответ Китая: на международном уровне ожидается, что за счет продвижения модели «высокоэнергетическая батарея + экологически чистое производство электроэнергии» выбросы углерода на протяжении всего жизненного цикла литиевых батарей могут быть сокращены на 25%, что обеспечивает технический путь и рыночное преимущество для производителей оборудования, ориентированного на экспорт.

4. Ключевые моменты: Устойчивость экспорта литиевых батарей из Китая совершенно очевидна.

Несмотря на многочисленные политические проблемы, экспорт литиевых батарей из Китая по-прежнему демонстрировал сильную динамику в первом квартале 2025 года (примечание: в качестве примера здесь используются фактические данные за первый квартал 2024 года; данные за первый квартал 2025 года еще официально не опубликованы):

Общий объем экспорта: 128 ГВтч, что на 28% больше, чем в предыдущем году.

Общий объем экспорта: 8,5 млрд долларов США, рост на 32% в годовом исчислении.

Структура экспорта и основные рынки сбыта литиевых аккумуляторов в Китае в первом квартале 2025 года

Основные экспортные продукты | Доля объема экспорта | Доля экспорта в стоимости (оценочная) | Основные целевые рынки |

Мощность аккумулятора | 61% | ~65-70% | Германия, США, Франция Аккумуляторная батарея |

Аккумуляторная батарея | 27% | ~20-25% | США, Южная Африка, Вьетнам |

Аккумулятор для бытовой электроники | 12% | ~10-15% | Корея, Индия, Мексика |

Доминирует аккумуляторная энергия: на ее долю приходится более 60%, это основная экспортная сила, в основном направляемая в Европу (Германия, Франция) и Северную Америку (США), где развита автомобильная промышленность.

5. Стратегии реагирования и перспективы на будущее

В условиях все более сложной политической обстановки производителям оборудования для литиевых батарей необходимо принять многомерные проактивные стратегии:

5.1 Технологические исследования и инновации:

Модернизация основного оборудования: постоянные инвестиции вкладываются в разработку нового поколения производственного оборудования, отвечающего требованиям высокоточного кодирования, высокой безопасности, высокой энергоэффективности и низкого уровня выбросов (например, высокоскоростное и высокоточное оборудование для ламинирования/намотки, интеллектуальные системы лазерной маркировки, энергосберегающее оборудование для сушки/зарядки).

Интеллектуальность и цифровизация: Глубокая интеграция технологий искусственного интеллекта, больших данных и Интернета вещей для повышения уровня интеллекта оборудования (прогностическое обслуживание, самооптимизация процессов) и возможностей цифровой прослеживаемости, отвечающих требованиям управления всем жизненным циклом.

Новые материалы/новое технологическое оборудование: перспективная компоновка ключевого оборудования, необходимого для технологий следующего поколения, таких как твердотельные аккумуляторы, натрий-ионные аккумуляторы и технология сухих электродов.

5.2 Углубление управления соответствием и стандартных исследований:

Создайте профессиональную команду: создайте отдел исследований нормативного регулирования или назначьте специалистов для мониторинга последних мировых (особенно в Европе и США) политик и правил (транспорт, охрана окружающей среды, безопасность, переработка) в режиме реального времени.

Активная сертификация: активно получайте международные авторитетные сертификаты (такие как стандарты CE, UL, IEC) для повышения глобальной доступности продукта.

Соответствие цепочке поставок: усиление ESG (окружающая среда, общество, управление) и управления прослеживаемостью материалов поставщиков, а также соблюдение требований Закона ЕС об аккумуляторных батареях и других нормативных актов для цепочки поставок.

5.3 Оптимизация цепочки поставок и локализованная компоновка:

Контроль затрат: за счет бережливого производства, крупномасштабного производства и интеграции цепочки поставок можно сократить производственные затраты и смягчить давление, вызванное ростом затрат, например, тарифов.

Глобальная схема: для рынков с высокими тарифами (например, США) оценить возможность создания производственных, сборочных или сервисных баз в третьих странах (Мексика, Восточная Европа, Юго-Восточная Азия) или на внутренних рынках целевых стран для достижения «диверсификации мест производства».

Оптимизация логистики: сотрудничество с профессиональными партнерами по логистике для оптимизации транспортных планов (преобладают морские перевозки, дополняемые воздушными), гарантируя соблюдение всех соответствующих транспортных правил.

5.4 Расширение диверсифицированных рынков и экологичный маркетинг:

Расширение на развивающихся рынках: увеличение инвестиций в потенциальные рынки, такие как Европа (страны, не входящие в ЕС), Юго-Восточная Азия, Южная Америка, Ближний Восток и Африка.

Экологическое ценностное предложение: подчеркивает ценность оборудования, помогающего клиентам сократить углеродный след аккумуляторов, повысить энергоэффективность, минимизировать отходы и поддерживать переработку, что соответствует глобальной тенденции к устойчивому развитию.

5.5 Схема циркулярной экономики:

Оборудование для переработки отходов: особое внимание уделить требованиям к оборудованию для переработки и демонтажа аккумуляторных батарей, а также процессам регенерации и утилизации, разработать эффективное и экологически безопасное оборудование для переработки отходов и расширить производственную цепочку.

6. Перспективы на будущее:

Глобальный энергетический переход и тенденция к электрификации необратимы, и ожидается, что спрос на литиевые батареи останется высоким в долгосрочной перспективе. Однако политика и правила будут продолжать становиться строже, фокусируясь на трех основных аспектах: безопасность, защита окружающей среды (низкий уровень углерода/переработка) и прослеживаемость. Основная конкурентоспособность производителей оборудования будет отражаться в:

- Можете ли вы предоставить передовое оборудование, которое сможет удовлетворить производственные потребности будущих технологий аккумуляторов (с более высокой производительностью, большей безопасностью и большей устойчивостью)?

- Сможет ли он быстро адаптироваться и соответствовать сложным и постоянно меняющимся нормативным требованиям в разных регионах мира?

- Сможет ли он эффективно осуществлять глобальное распределение ресурсов, расширение рынка и управление рисками.

- Соответствует ли само оборудование и обслуживаемый им производственный процесс требованиям низкоуглеродной и циклической экономики?

Внутренние и международные политики и правила установили более высокие стандарты для отрасли литиевых батарей, и в то же время они глубоко изменили конкурентную среду производителей оборудования. Проблема заключается в постоянном росте затрат на соответствие и технических порогов; возможность заключается в технологической модернизации, зеленой трансформации и расширении глобального рынка. Только те производители оборудования, которые могут тонко воспринимать тенденции политики, постоянно инвестировать в технологические инновации, гибко оптимизировать глобальные стратегии и твердо следовать по пути зеленого и устойчивого развития, могут одержать верх в эпоху постоянных изменений и оставаться непобедимыми.